-

-

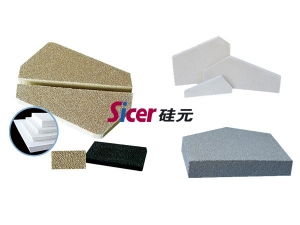

Zirconium Oxide Filter

Zirconium oxide filter is produced from high purity zirconia offering unique features of high strength, no slag, high refractoriness, thermal shock resistance, homogeneous pore and precise size. It is intended for use in the filtration of casting copper, stainless steel, carbon steel and other hot alloy melt below 1700°C. It can effectively filter non-metallic particles, slag and refractory material pieces as small as micron size, thus improving qualified product rate of casts by improving casts microstructure and reducing internal reoxidisation defects. It also reduces mould wear and simplifies gating system. We can provide you filters of different dimensions and shapes, and tailor-made filters to meet your requirements.

|

Material |

Zirconium oxide |

|

Temperature (°C) |

≤ |

|

Color |

Yellow |

|

Pore (ppi) |

4~60 |

|

Porosity (%) |

80~90 |

|

Compressive Strength (MPa) |

≥1.8 |

|

Bulk Density (g/cm3) |

1.0~1.5 |

|

Thermal Shock Resistance (times/ |

6 |

|

Quality Standard |

JC/T895-2001 |

- PreviousSilicon Carbide Filter

- NextAluminium Oxide Filter